How to Improve Employee Engagement in Manufacturing Industry: 15 Strategies for a Productive Workforce

The manufacturing industry faces challenges like labor shortages, skill gaps, and high turnover. Understanding how to improve employee engagement in manufacturing can help businesses boost productivity, reduce absenteeism, and retain top talent.

On this page

The manufacturing industry plays a crucial role in driving economic growth, yet it faces significant workforce challenges, including labor shortages, skill gaps, and high turnover rates. According to recent data, 83% of manufacturers consider attracting and retaining talent as their biggest challenge, making employee engagement in manufacturing more critical than ever.

Despite its importance, engagement levels remain low. A Gallup study found that only 20% of employees globally feel engaged at work, with US engagement levels slightly higher at 36%.

However, improving manufacturing employee engagement can lead to higher productivity, fewer safety incidents, reduced absenteeism, and better employee retention.

To create a more motivated and committed workforce, manufacturers must focus on how to improve employee engagement in manufacturing through better workplace culture, career development opportunities, and effective communication strategies.

In this blog, we’ll explore practical approaches to help manufacturing companies build a more engaged and productive workforce.

How to engage manufacturing employees: 15 effective strategies

Here are four effective ways of employee engagement in manufacturing industries.

1. Align company goals with employee goals

Maintenance or warehouse employees often don't experience the end product. This lack of emotional involvement can quickly result in disengagement.

You can fix this by explaining to your employees the bigger picture. They need to understand how their daily tasks fall into the big-picture goals of the company. How are they helping the organization? What’s their contribution?

Try to foster a sense of purpose by sharing the company's mission and values with your employees. Remind them of the impact that their work has on the company, the final product, the customers, and the broader community.

2. Create a safe work environment

This one is a no-brainer — make sure that your employees have the right tools, safety equipment, protocols, and protection mechanisms necessary to safely do their jobs.

Manufacturing jobs can be physically demanding. So, consider providing amenities such as break rooms, on-site healthcare, or ergonomic equipment.

Note that manufacturing is among the top in job-related injuries in the workplace, with an average of over 400,000 non-fatal injuries. Some common dangers are:

- Slips, falls, and trips

- Electrical dangers

- Production machines

- Heavyweight or powered industrial vehicles

- Other environmental hazards

For example, consider an employee who works on a production line assembling small parts. If you don’t provide them with protective eyewear, they risk eye injuries if small debris or particles get into their eyes.

Another example is an employee who works with sharp tools or materials without wearing protective gloves. They're running the risk of injuries like cuts, abrasions, or worse.

These are just two examples of why safety equipment is important in manufacturing - it helps protect employees from potential injuries and enables them to work safely. Without this basic right, employee engagement will always be lacking.

3. Offer flexible work schedules

When we talk about a flexible work schedule, we often go in two directions — flexibility of location or work hours.

In the manufacturing industry, remote working often won’t be a possibility. However, that doesn’t mean you can’t offer other types of flexible schedules:

- Flextime — flexibility in choosing work hours

- Compressed workweek — working those 40 weekly hours divided differently from the standard 5-working day week/8 hour-days (for example, working 10-hour days from Monday to Thursday and then having Friday, Saturday, and Sunday off)

- Part-time — working half the regular time (often needed in the case of shift workers, students, etc.)

- Hybrid schedules — location-wise, working partly remotely, partly in-office

A large part of an employee’s satisfaction and work-life balance comes from regular breaks between shifts, paid time off, and consistency. Unfortunately, frequent overtime is common in manufacturing.

But good employee scheduling software can automate and streamline scheduling, shift swapping, and last-minute replacements — avoiding unnecessary overtime.

4. Provide career development opportunities

Any employee that steps into a company looks for compensation and growth in a manner that they can move up within the organization. According to a Glint and LinkedIn report, 97% of employees said that they would appreciate more learning opportunities and time for learning.

Manufacturing companies also need to regularly upgrade employees’ knowledge of new safety rules and regulations for their well-being.

And this training ultimately improves their performance and helps you vouch for their productivity to other departments and end consumers. For example, logistics companies aiming for faster delivery and better customer experience extensively rely on workers' training and motivation at the micro fulfillment centers.

Implementing training and development programs at regular intervals increases engagement and helps with retention as well. Because a lack of engagement generally stems from the reason that workers don’t have growth opportunities, or they don’t have the required skills to be ready for bigger roles.

Some examples of career growth within a company are:

- From production technician to production manager

- From quality inspector to quality manager

- From production worker to machine operator

- From machine operator to supervisor

So, if your goal is to end up with a loyal maintenance workforce, offering career development and continuous learning opportunities should be at the top of your list of priorities.

5. Make employees feel valued and appreciated

Who doesn’t like recognition for the good work they do? This works even better than the pay sometimes. In fact, research suggests that manufacturing workers who felt valued were more than four times as likely to report high levels of employee engagement (59% vs.13%) and less likely to say they feel stressed out on a typical workday (16% vs. 66%).

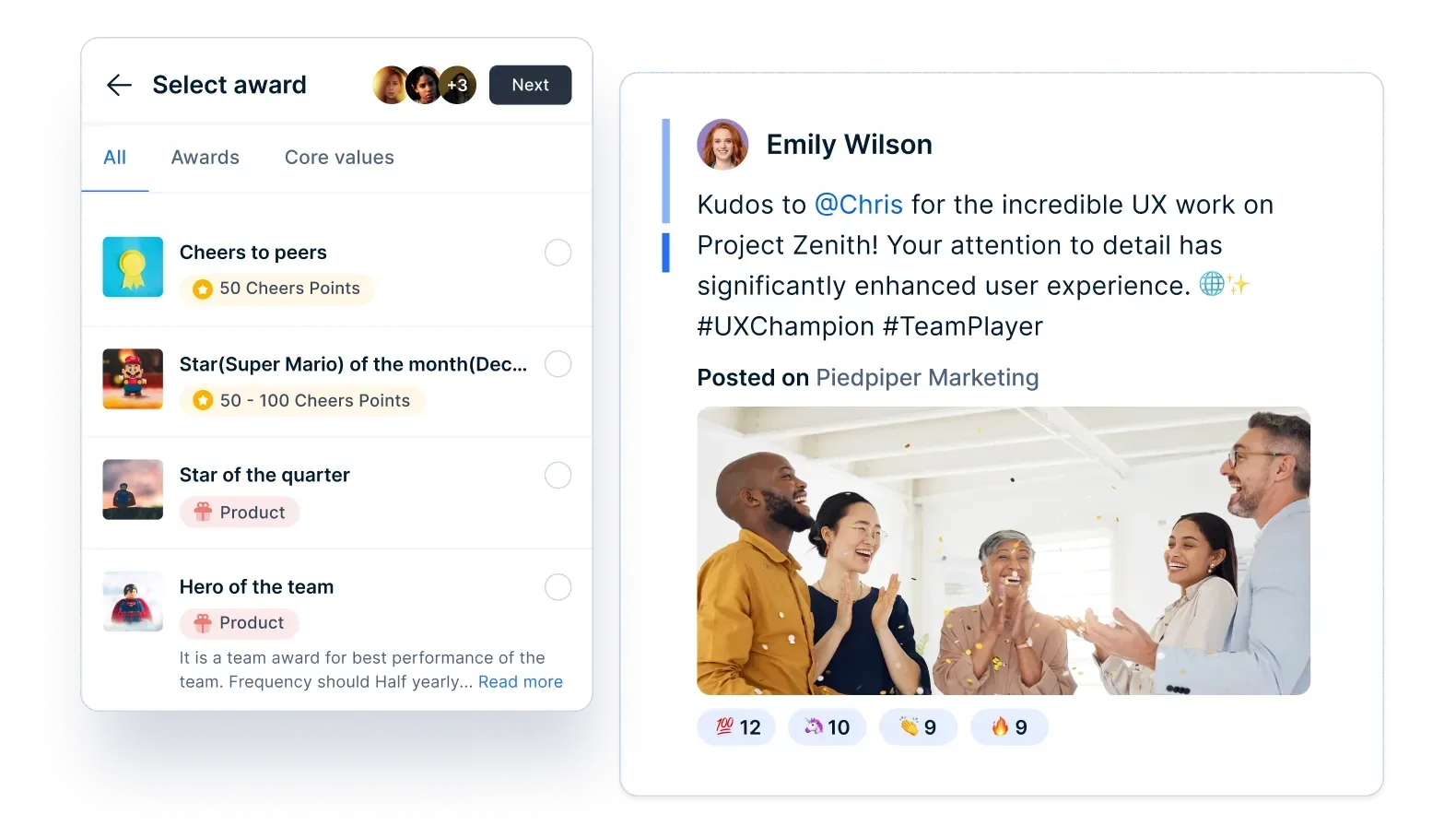

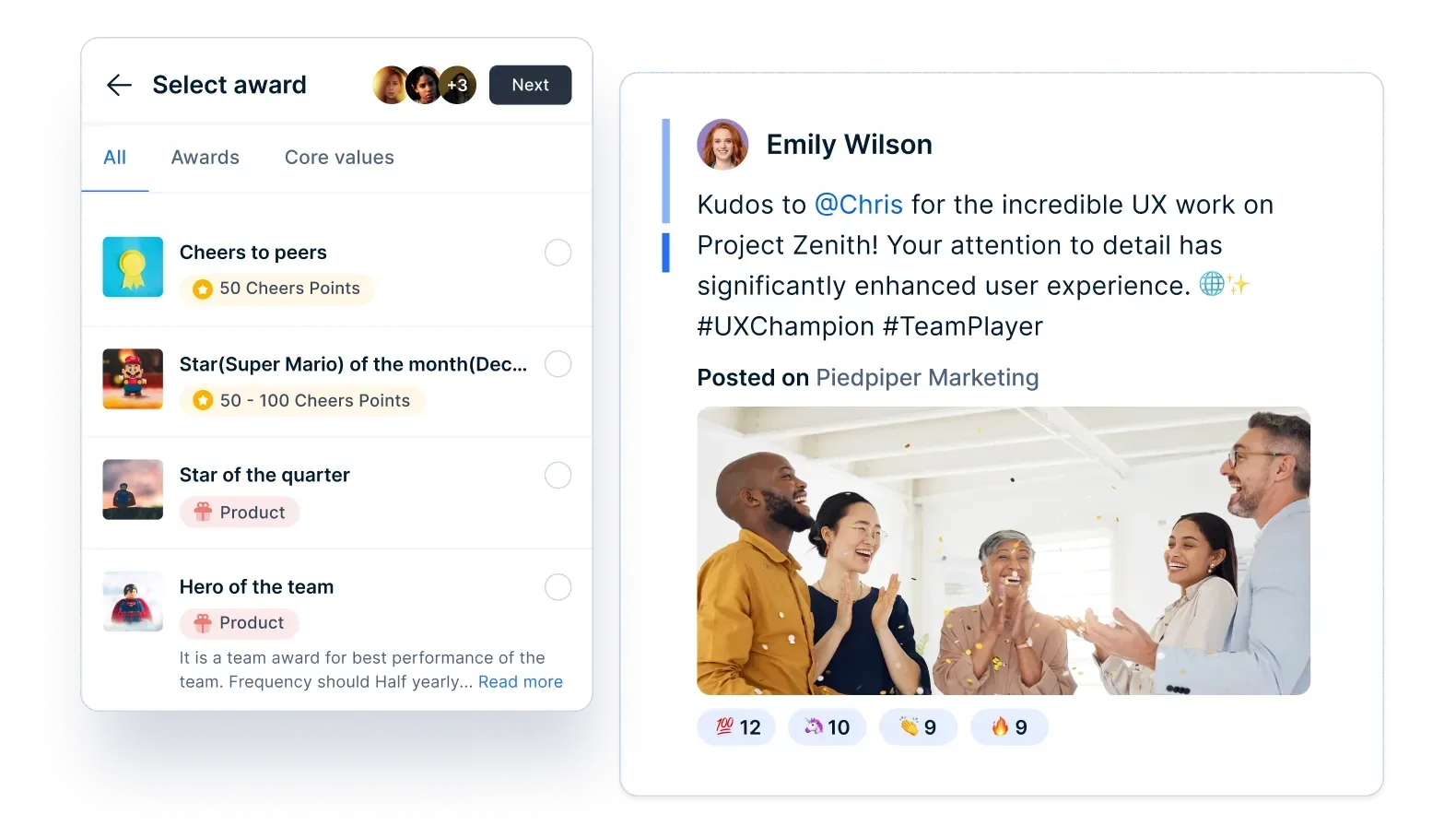

When we talk about changing perspectives, companies cannot take manufacturing employees for granted. To recognize employees, renowned companies are now leveraging employee recognition software to implement peer-to-peer recognition platforms, give shot-outs, and send appraisal emails to everyone in the team to highlight the good work and keep the workers’ spirits high.

They’re also holding employee-of-month meetings where everyone celebrates the winner. Focusing on the positive aspects of an employee helps them develop a positive perspective about the company and also increases their productivity and profits.

Recognition and appreciation can come in different forms. Ideally, personalized according to the job role or the individual needs of the worker. For instance:

- Monetary rewards (bonuses, salary raise, gift cards, etc.)

- Public (or private, depending on the individual) verbal praise or a shout-out

- Written recognition (for example, a hand-written note of appreciation)

- Friendly contest awards (such as employee of the month)

- Special perks or privileges for top performers

- Other ways of recognition (free course vouchers, etc.)

Well-structured employee rewards and recognition programs will help you boost engagement, productivity, and most of all, retention.

Additionally, making employees feel valued will help you build a positive culture and reputation within the organization, which can attract top talent and build customer loyalty.

Overall, making manufacturing employees feel appreciated is an important way to support the success and growth of the company.

6. Establish two-way communication channels

Many manufacturing employees work on the factory floor and don’t have regular opportunities to interact with management or share their ideas. So, encourage open communication by:

- Holding regular meetings with departments

- Setting up suggestion boxes where employees can voice their thoughts and concerns

Effective communication in the workplace starts by being able to listen and showing empathy to your coworkers. That’s why it’s crucial to lead by example and show interest in your employees’ ideas and suggestions so that they aren’t afraid of voicing their concerns.

Another helpful way to improve communication is mobile and on-the-go solutions for communicating with frontline or remote workers. With tools like that, your deskless employees will stay in the loop and be informed of all important company updates.

7. Compensate your employees fairly

Fair compensation is the pillar of any business headed for long-term success, here’s why:

- Helps you attract and retain top talent

- Promotes values such as fairness and equality

- Improves employee morale, engagement, motivation, and productivity

- Builds loyalty and trust

- Supports the financial well-being of employees.

Many factors go into fair compensation:

- Establishing a clear and transparent pay structure with salary ranges defined for every job role

- Following and complying with labor laws and regulations such as equal pay and minimum wage requirements

- Conducting salary surveys to find the benchmark for your industry and adjust your salary offers accordingly

- Regular compensation review (take into account the employee’s experience, contribution, market changes, or living cost escalation)

- Clearly explaining bonus structures and extra pay

8. Improve your onboarding process

Employee engagement should start at onboarding. Why? Because you cannot expect your employees to be engaged and productive if they don’t understand their tasks and what they’re doing in the first place.

A well-designed onboarding process helps new employees feel supported and valued. Here are some tips to help you improve your onboarding:

- Provide the necessary technology and tools needed for the job

- Provide access or entry badges

- Create and provide account login data (usernames, passwords)

- Give a welcome package (relevant training documents, role responsibilities, small corporate gifts, etc.)

- Outline clear job role expectations, KPIs, and goals, and explain the process of evaluating performance

- Assign a mentor or implement job shadowing as a way to help new employees acclimate to their new role and learn the ropes more quickly

- Provide compliance and safety training

- Offer ongoing training and development opportunities

- Provide regular constructive feedback

To save time and automate onboarding, you can use software to create a type of self-service for new hires. In that way, they can access information at all times, which is an important practice for manufacturing jobs.

9. Use employee engagement tools

In the past, it was difficult to manually structure employee engagement programs and put them into practice. Luckily, today, you can streamline all your employee engagement efforts using technology and software. Tools like that give you a holistic approach since they contain everything that goes into a well-structured engagement program:

- Employee communication

- Rewards and recognition

- Employee surveys

- Data and employee analytics

- Performance tracking

Luminous Power Technologies is an Indian company for home electrical solutions with seven manufacturing units and 28 sales offices in India. Their Rewards & Recognition (R&R) process was not standardized and lacked creativity and variety, leading to many employee requests for a better process.

So, Luminous decided to digitize their R&R program with Empuls since it integrates with the company's existing systems and offers a wide range of reward options.

The platform was well-received by the company's employees, particularly blue-collar workers who had not previously been exposed to such platforms. Implementing Empuls helped improve employee engagement and anchor the company's core values in the R&R process.

Build a Motivated Manufacturing Workforce with Empuls

Long shifts and demanding work environments can lead to disengagement. Keep employees motivated with meaningful rewards, real-time feedback, and seamless communication designed for the manufacturing industry.

10. Promote colleague engagement

The manufacturing sector can be quite a stoic and rough environment to be in. To change the trajectory of the manufacturing industry, companies have started encouraging employees to socialize with one another. They are creating an environment where employees are more comfortable being empathetic towards one another. This allows employees to reach out to their colleagues for any help which prevents accidents and fosters a more satisfying work environment.

For example, Shell’s oil rig workers were made to attend a seminar amid rising accidents. The company conducted sessions with respected leadership consultants where employees were encouraged to open up and talk about their personal experiences on the field with just the motive to get closer to one another. The sessions had a drastic impact on the employees, so much so, that the company's accident rate decreased by 84%, and worker productivity improved significantly.

Workshops are just one means to encourage engagement among employees. You can also take baby steps to encourage employees to interact. You can have ice-breaker sessions and activities, start meetings with informal chit-chat, and even allocate special interactive sessions. Once they develop work relationships on a slightly personal level, they will look forward to coming to work and be encouraged to stay.

11. Ensure management and HR are approachable

The role of HR in employee engagement is undeniable, in manufacturing and every other industry. It starts from providing properly structured onboarding to resolving conflicts fairly and, of course, designing continuous career and development opportunities.

Instead of being cooped up in their office the whole day, HR teams should be available to employees and make an effort to visit the factory floor regularly. They should be approachable and willing to listen to employee concerns and ideas and act on critical feedback. This shows employees that their input is valued.

Furthermore, the role of the manager goes more than ensuring the job gets done. It’s about providing support and the right resources needed to successfully do the job. Here’s how management can boost employee engagement:

- Improve soft skills and communication with training

- Establish regular check-ins and 1:1 meetings with team leaders, shift managers, and other responsible manufacturing employees

- Implement programs like coaching, mentoring, or job shadowing when appropriate

- Regularly visit factory floors and interact with manufacturing employees

12. Create a culture of collaboration

Effective collaboration and teamwork are critical in the manufacturing industry. Many employees frequently handle complex projects or operate heavy machinery. To promote teamwork, companies should cultivate a culture of cooperation and provide opportunities for employees to collaborate and support one another.

Here are some practical ways you can use to promote collaboration across teams:

- Lead by example and remain open to feedback and input from employees

- Promote inclusivity and involve employees in the decision-making process

- Provide the technology and tools that enable employees to communicate and work together remotely

- Recognize and reward employees for their teamwork

- Try cross-functional projects where different teams and departments have to work together

- Implement team-building activities to foster a sense of friendship and togetherness

- Encourage and celebrate employees who speak up and share ideas, even if they’re not always implemented

So, they started an initiative where they give employees paid time off to volunteer and make an impact. With this move, they contribute to society and boost teamwork among their employees.

13. Celebrate milestones and accomplishments

Celebrating accomplishments is a way to recognize and reward employees for their hard work and contributions, which can help improve morale and motivation. In return, this will improve retention since employees are less likely to leave an organization that values their achievements.

Milestones are another way to celebrate employees and create a positive culture in your organization.

Here are some ideas:

- Send a company-wide shout-out email for a job well done or a successfully finished project

- Celebrate work anniversaries and show appreciation for the employee’s loyalty

- Write a card or a hand-written “thank you” note

- Give a small gift or organize a get-together to celebrate an accomplishment or a work anniversary milestone.

Reward and Recognize Your Manufacturing Workforce with Empuls

Hard work on the production floor deserves more than just a paycheck. Celebrate safety milestones, exceptional performance, and teamwork with meaningful rewards and recognition programs designed for manufacturing employees. Keep motivation high and retention strong.

14. Encourage health and wellness programs initiatives

Your employees’ work-life balance, as well as their physical and mental health, should be one of your top priorities. In an industry like manufacturing — where workers need to have razor-sharp focus — the health of employees becomes even more of a concern.

Health and wellness programs are a great way to ensure your workers remain healthy. For your company, healthy workers translate to increased productivity, increased retention, reduced absenteeism, and a better reputation.

Here are a few practical examples of programs you could implement:

- On-site fitness classes or gym memberships

- Regular health screenings to identify any potential concerns

- Nutrition and healthy eating programs

- Stress management and mindfulness programs

- Access to counseling and other support services to manage stress and other mental health concerns.

15. Clearly define compensation terms and yearly hikes

Above, we mentioned that it’s important to compensate your employees fairly. So, as our last point, we’d like to add to that and talk about the importance of clearly defining the compensation terms in advance, along with the planned yearly salary hikes.

Here are some great practices:

- Create a transparent compensation structure to make it clear how their salary is determined and what to expect in terms of salary increases

- Clearly communicate the criteria or KPIs needed for a salary increase

- Establish an annual performance review tied to a salary review

- Explain other forms of compensation in a structured way (for example, bonuses, over-hours, and other benefits)

16. Equip employees with the necessary tools

Without the right tools, employees' productivity and engagement will suffer. This is especially true in the manufacturing industry where companies manage custom complex workflows and procedures. For manufacturing workers, documentation is crucial to do their job right.

Additionally, employees on the factory floor often have limited access to technology and devices on the job site. As a result, they’re often excluded from company news and are out of the loop, which is a huge cause for disengagement.

To avoid losing engagement, ensure that your employees have access to the right tools, such as:

- Central documentation storage for training information, safety policies, processes, manuals, guidelines, and workflows

- Tools for internal and external communication and collaboration

- The right equipment or machinery needed for the job role

- Mobile tools for real-time company-wide updates and on-the-go support.

They literally asked employees what they should invest in to make their lives at work better. In the end, they installed an AC based on the employees’ wishes. This is a great example of listening to your employees and giving them what they really need.

Keep your manufacturing workforce motivated and engaged with Empuls

On the factory floor, in warehouses, and across production lines, employees keep operations running smoothly. But long shifts, demanding schedules, and limited recognition often lead to disengagement, low morale, and high turnover.

Investing in employee engagement solutions for manufacturing isn’t just about boosting productivity—it’s about creating a workplace where employees feel valued, motivated, and committed to their roles.

Empuls transforms employee engagement in the manufacturing industry by integrating recognition, communication, and feedback into everyday workflows—helping organizations build a stronger, more connected workforce.

How Empuls Creates a More Engaged Manufacturing Workforce:

- Recognize effort beyond the numbers: Celebrate safety milestones, shift performance, and teamwork with meaningful rewards that truly resonate.

- Turn employee feedback into action: Capture real-time insights through surveys and analytics to identify challenges and drive workplace improvements.

- Bridge the communication gap: Use a social intranet to keep factory and frontline workers informed, connected, and engaged across shifts.

- Offer perks that matter: Show appreciation with tax-free benefits, milestone rewards, and incentives tailored to manufacturing employees' needs.

- Boost retention & performance: Keep employees motivated with structured rewards and recognition programs that reinforce positive behaviors and achievements.

Manufacturing success isn’t just about efficiency—it’s about people. With Empuls, organizations can create a thriving culture of appreciation, connection, and continuous improvement, ensuring employees stay engaged and committed for the long haul.

Key takeaways for skyrocketing employee engagement

Employee engagement in manufacturing is essential to address challenges like labor shortages, skill gaps, and high turnover. Aligning company goals with employee objectives ensures they understand their impact. A safe work environment, with proper tools and amenities, boosts morale and retention.

Providing career development opportunities fosters growth and commitment. A holistic approach that includes goal alignment, safety measures, flexible work schedules, and learning opportunities can significantly improve manufacturing employee engagement and workforce stability.